Revolutionising SPINCap® Testing with Collaborative Robotics: A Step Forward in Electronics Manufacturing Excellence

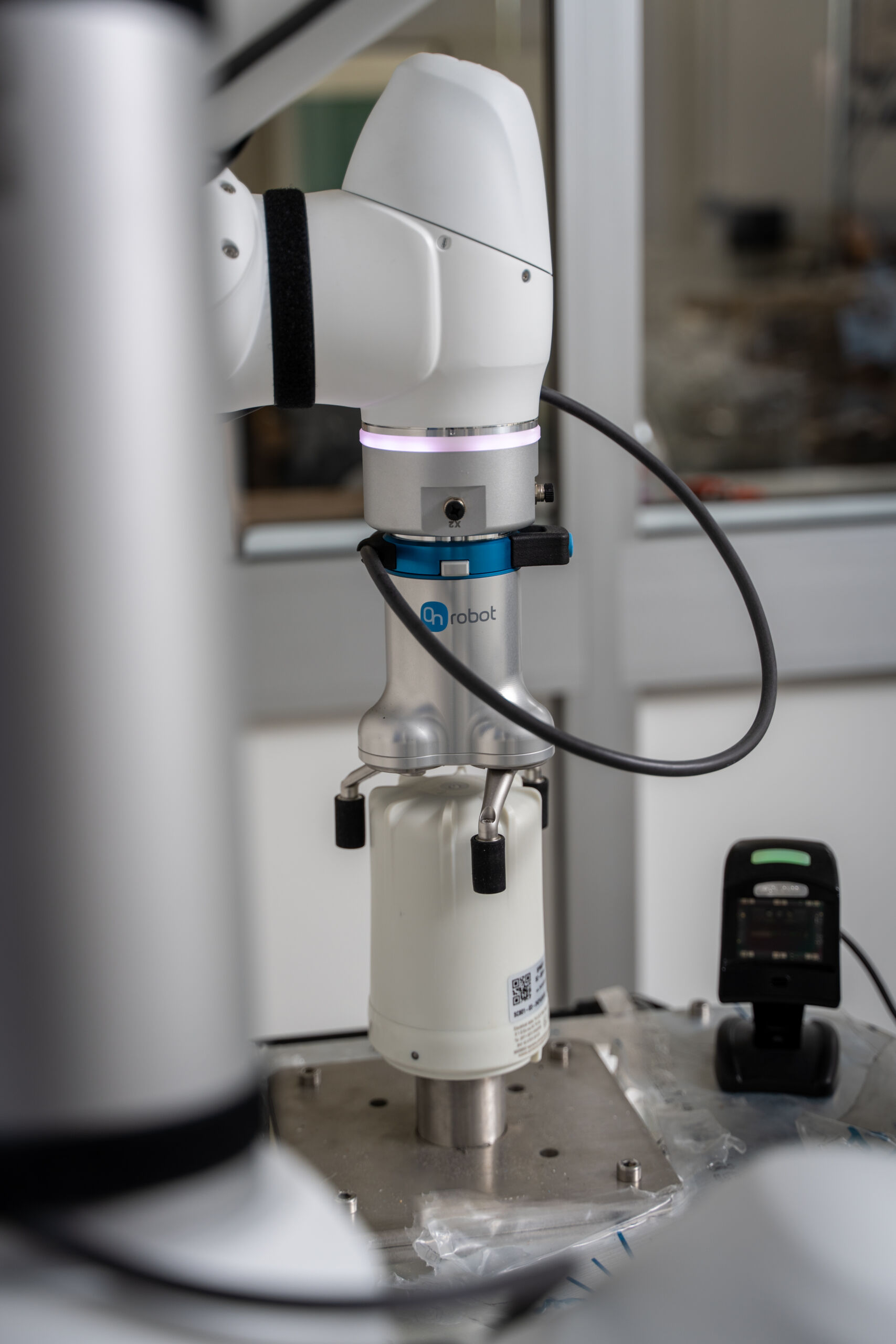

At TCL Group, we are constantly striving to improve the quality, safety, and efficiency of our electronic manufacturing processes. A key example of this ongoing innovation is the recent integration of a collaborative robot (cobot) into the testing and validation phase of SPINCap®, our proprietary smart cap system designed for LPG tanks.

SPINCap® is a flagship product developed by SPIN System (a product line of TCL Group), recognised across the Oil & Gas industry for its ability to enhance safety, security, traceability, and operational control. As production volumes grow, ensuring consistent quality and reliability during end-of-line testing becomes increasingly critical. That’s why we’ve taken a major step forward by introducing robotic automation into the process.

Why Automate SPINCap® Testing?

Traditional manual testing processes in electronics manufacturing, particularly in products like SPINCap®, can lead to variability, physical strain on operators, and slower throughput. By implementing a collaborative robot solution in collaboration with Homberger, we’ve created a more streamlined and repeatable process, without compromising the flexibility of human oversight.

Key Benefits of Robotic Testing for SPINCap®

1. Higher testing accuracy and consistency

The cobot performs a wide range of tasks including:

- Component assembly and disassembly

- Torque measurement and verification

- Functional testing of electronic circuits

- Mechanical performance analysis

This guarantees precise and repeatable testing cycles that reduce human error and improve final product quality.

2. Enhanced safety for operators

By automating repetitive, high-precision tasks, we significantly reduce operator fatigue and the risk of work-related injuries. The cobot works safely alongside human operators, embodying the core concept of collaborative robotics in industrial applications.

3. Increased productivity and throughput

Automated testing has allowed us to increase overall testing capacity, supporting higher production rates without compromising on accuracy. This results in shorter lead times and faster time-to-market: a key competitive advantage.

4. Real-Time data acquisition and traceability

Every test performed by the cobot is logged and integrated into our quality control system, providing real-time data for analysis, traceability, and continuous improvement.

5. Compliance with Industry 4.0 standards

This project is fully aligned with our broader Industry 4.0 roadmap, which includes digitalisation, process automation, and smart factory principles.

Watch the SPINCap® Robotic Testing in action

To see how this innovative robotic application works, and how it contributes to both product quality and workforce well-being, watch our latest case study video!

Click Here to watch the video with subtitles in your language!

The video showcases the implementation in action, highlighting the technical and operational improvements brought by this automation.

Looking ahead: innovation in electronics testing

With this successful implementation, TCL Group is setting a new standard in automated electronics testing. The adoption of collaborative robotics is not only transforming how we manufacture SPINCap®, but also shaping the future of our entire production ecosystem.

We remain committed to:

- Investing in intelligent automation

- Improving the repeatability and reliability of our testing processes

- Enhancing the safety and performance of our production environments

- Prioritizing workplace safety

- Striving for continuous improvement

- Maintaining a happy, engaged workforce that takes pride in their work

About SPIN System

SPINSystem is a line of products made in Italy by TCL Group, specialised in the development of innovative electronics for industrial applications. Learn more about SPINCap® and our smart solutions for the LPG sector at www.spinsystem.it.